what type of wood to make a playhouse door

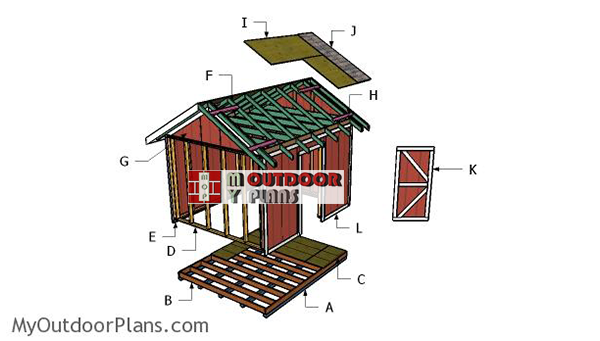

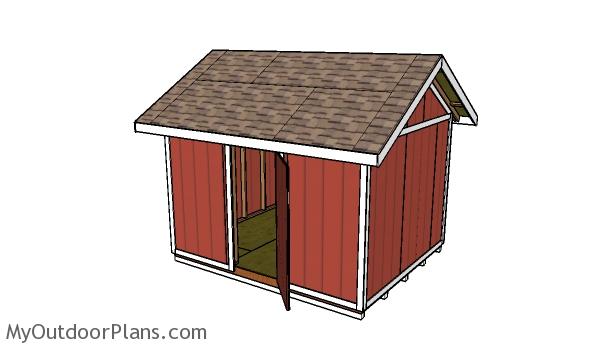

This step past stride diy project is nearly diy x×12 shed plans. I have designed this shed then you can store your garden tools and outdoor article of furniture in a stylish and durable style. This garden projection has more than parts so have a look over the residuum of the sections to learn how to build the roof and the door. Moreover, I have designed shed with many sizes so cheque them out, as well. Take a look over the rest of mywoodworking plans, if you want to become more building inspiration.

When buying the lumber, y'all should select the planks with great care, making sure they are direct and without any visible flaws (cracks, knots, twists, decay). Investing in cedar or other atmospheric condition resistant lumber is a good idea, as it will pay off on the long run. Utilise a spirit level to plumb and marshal the components, before inserting the galvanized screws, otherwise the project won't have a symmetrical look. If you accept all the materials and tools required for the project, you lot could get the chore washed in about a day. See all my Premium Plans Hither.

Projects made from these plans

x×12 Shed Plans

Building-a-10×12-outdoor-shed

- Materials

- Tools

- Time

- Related Plans

- A – 5 pieces of 4×iv lumber – 144″ long SKIDS

- B – 2 pieces of 2×6 lumber – 144″ long, 10 pieces – 117″long FLOOR

- C – iii pieces of 3/4″ plywood – 48″x96″ long, 3 pieces – 24″x48″ long FLOORING

- D – 2 pieces of 2×iv lumber – 113″ long, ane piece – 120″ long, half dozen pieces – 85″ long 2x SIDE WALL

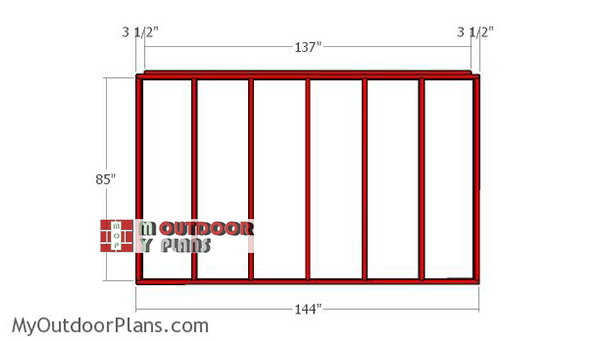

- D – 1 piece of 2×4 lumber – 144″ long, 1 piece – 137″ long, 2 pieces – 54″ long, eight pieces – 85″ long, 2 pieces – 39″ long, 2 pieces – 75 1/2″ long Forepart WALL

- D – two pieces of 2×4 lumber – 144″ long, 1 piece – 137″ long, vii pieces – 85″ long BACK WALL

- E – 10 pieces of T1-xi – 48″x96″ long, 2 pieces – 24″x48″ long SIDING

- ii pieces of 2×half-dozen lumber – 12′

- 10 pieces of two×half dozen lumber – 10′

- v pieces of 4×4 lumber – 12′

- four pieces of 3/4″ plywood – 48″x96″

- 6 pieces of 2×4 lumber – ten′

- half-dozen pieces of 2×iv lumber – 12′

- xxx pieces of two×4 lumber – eight′

- 11 pieces of T1-11 – 48″x96″

- 8d nails, two 1/2″ screws, 3 ane/2″ screws

- forest filler , wood mucilage, stain/paint

One 24-hour interval

Building a free ten×12 shed

Building-the-shed-floor-frame

The first footstep of the projection is to frame the floor for the 10×12 shed. Cut the floor joists from 2×6 lumber at the correct dimensions using a expert saw. Smoothen the edges with sandpaper and marshal the components with attending. Make certain the corners are right-angled and drill pilot holes through the rim joists. Insert 3 1/ii″ screws to lock everything together tightly.

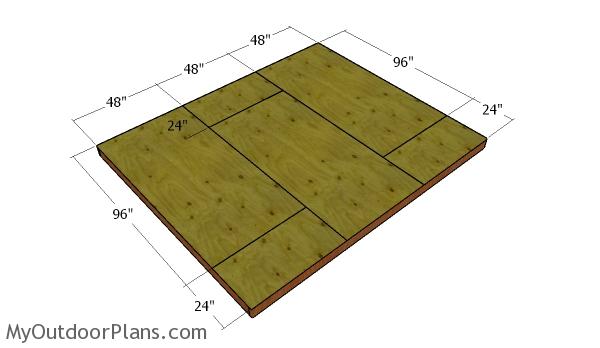

Attaching the flooring

Next, attach the 3/four″ natural language and groove plywood sheets to the joists. Align the sheets with attention and insert 1 1/4″ screws to lock them into identify tightly. Get out no gaps betwixt the sheets for a cracking result.

Attaching the skids

Continue the project by attaching the iv×4 skids to the floor frame. Place the skids as spaced and lock them to the joists with ties.

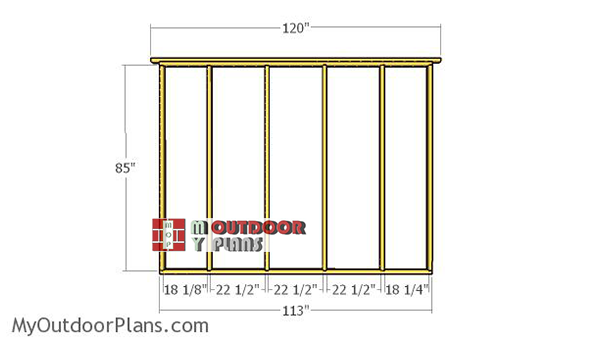

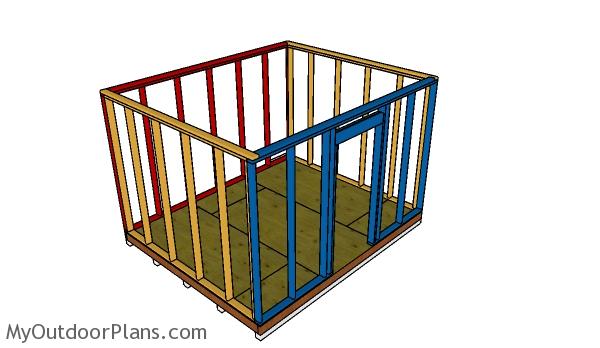

Edifice-the-side-walls

Assemble the side walls from 2x4s. Make certain you cut the studs and the plates at the right dimensions. Drill pilot holes through the plates and insert 2 one/two″ screws into the studs. Place the studs every 24″ on center, making certain the corners are foursquare and the edges flush.

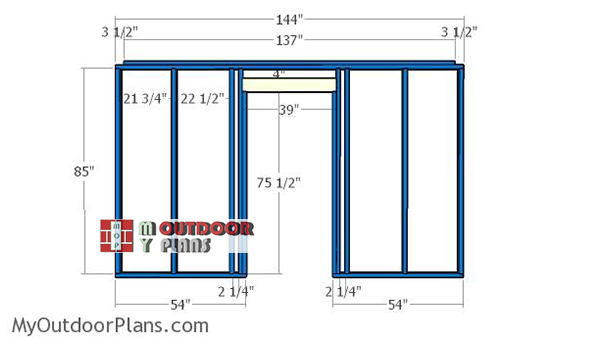

Building-the-front-wall-frame

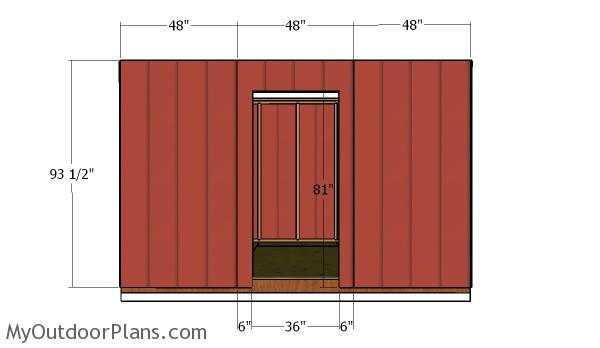

Continue the project past assembling the font wall for the gable shed. As y'all tin can easily notice in the diagram, you demand to frame the door opening.

Building-the-back-wall-frame

Next, frame the back wall for the ten×12 shed. Assemble the walls on a plane flooring, making certain the corners are square and that all joints are rigid.

Fitting the front and back walls

Later assembling the wall frames yous need to install them to the flooring of the shed. Align the edges with attention and apply a spirit level to plumb them before locking them into place tightly. Utilise temporarily braces to lock the front and back walls to the floor. Drill airplane pilot holes through the bottom plates and insert 3 one/ii″ screws into the floor frame.

Fit the side walls to the shed, as shown in the diagram. Insert the screws through the bottom plates into the

Fitting the side walls

Build the exterior walls from 5/viii″ T1-11 siding. As you can notice in the diagram, y'all need to make some cuts to the sheets so you cover the whole surface. Employ 8d galvanized nails to secure the sheets to the wall frames. Marshal everything with attention and insert the nails every eight″ forth the studs.

Fitting the front sheets

Make the cuts to the canvas that goes around the door opening. Marshal everything so the edges are flush and secure them into place with 8d nails.

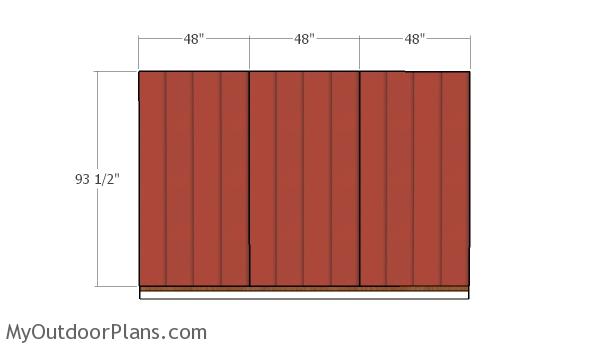

Dorsum Wall

Attach the residual of the sheets to the back wall of the shed. Marshal the edges with attention and secure them to the wall studs with 8d nails or screws. Brand sure y'all get out no gaps between the sheets for a professional result.

ten×12 Shed Plans

Brand certain yous check out the rest of the project, so you learn how to frame the roof and how to attach the door and the trims to the shed. In add-on, I have lots of other shed projects on the site so I recommend you to scan through all alternatives before starting the edifice project.

This woodworking projection was most 10×12 shed plans costless. If you want to run across more outdoor plans, check out the balance of our step by step projects and follow the instructions to obtain a professional person result.

Source: https://myoutdoorplans.com/shed/10x12-shed-plans/

0 Response to "what type of wood to make a playhouse door"

Post a Comment